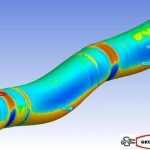

3D animation of rotary kiln shells

Measurements of rotary kiln shell deformation constitute a significant part of our extensive offer of kiln inspection.

Geoservex was the pioneer in the field of these measurements, covering the scope ranging from simple measurements of distance and geometric approximation of a cross-section shape, to linear laser scanning and unique computer software development enabling the calculation of shell eccentricity in a particular cross-section and its shape deformation (circularity).

The next step of the development of this service is our newest product – a three-dimensional computer animation of a rotating kiln shell, presenting its measured shape deformations (cross-section eccentricity and circularity deformations). Additionally, this model has been enhanced with a visualization of tyres rotation together with their wobbling (axial unbalance) and radial run-out.

A combination of all the parameters in one virtual graphic model creates a perfect tool to assess the state of the kiln shell, the reason for tyre and drive ring unbalance, as well as to plan repairs, replacement of some parts of the shell, and to plan correction cuts. Moreover, a comparison between the shell deformation and the measurements of support roller shafts deflection enables the detection of mechanical crank formation, and with additional temperature measurements, also of the shell thermal crank formation.

The shell computer animation has been prepared in a way that, despite its advancement, it is easily operated. Therefore, the end product is saved in the PDF format and can be opened and viewed with a popular and free Acrobat Reader 8.