Hot kiln alignment, adjustment and inspection

The method was patented by GeoServex S.C., and used over 1,000 times in 42 countries of the world, which reflects its reliability. Till this day, no other measurement method guarantees a higher accuracy for the measurement of kiln alignment.

Besides the obvious benefits resulting from kiln alignment in dynamic conditions (higher reliability, less emergency standstills, extended useful life of refractory lining and kiln components, lower power consumption of drive [amperage], limiting the problem of hot bearings, etc.) choosing GeoServex gives additional benefits compared to competitive companies. These include:

- Highest currently achieved accuracy of kiln axis measurements (+/- 0.5 ÷ +/- 1 mm).

- Measurement of roller shaft axis location (geometrically in relation to the actual kiln axis in the vertical and horizontal plane).

- Unique solutions, e.g. measurement of drive meshing during normal operation.

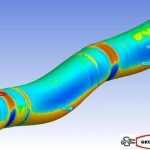

- Detailed laser measurement of kiln shell (radial deformations and eccentricity).

- Preparation of 3D kiln shell deformation model.

- Optimization of kiln adjustment option for many conditions, sometimes contradictory, taking into account the degree of wear and tear of kiln components.

- Supervision over kiln adjustment (roller dislocation during normal kiln operation).

- Control measurement of the kiln axis after performed adjustment.

- Drawing up a detailed report on performed kiln alignment works with guidelines for the customer and presentation of report with discussing details and possible vagueness in the customer’s office.

The scope of performed measurements carried out as part of our kiln alignment services is too extensive to be mentioned here. So, call us TODAY for clarification, customers list and testimonials.