WoR Rotary Kiln Refractory Insulation

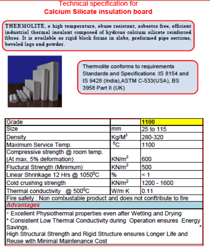

Manufacturers and operators of industrial heating equipment (furnaces, boilers, and kilns) are constantly looking for ways to reduce the large energy losses that occur through the surfaces of their heating equipment.

The recent trend of rising energy costs reinforces the need to reduce these heat losses even further. One proven and effective way to combat energy losses and the resulting high energy bills is to optimize the selection of thermal insulation materials (i.e : refractory and insulating materials) used in process heating equipment.

Some new and emerging thermal barriers on the market are opening up attractive opportunities to leverage refractory materials for energy savings and productivity gains while protecting the structural integrity and operability of heating equipment.

Insulating refractory systems work to enhance energy efficiency in two ways:

- Reduce energy loss through the structure walls (thermal conductance); and

- Minimize heat storage in the walls (thermal capacity), which lowers startup and shutdown losses.

With escalating energy prices, new refractory and insulation materials that were once considered expensive are now turning out to be good investments, promising significant reduction in energy bills.