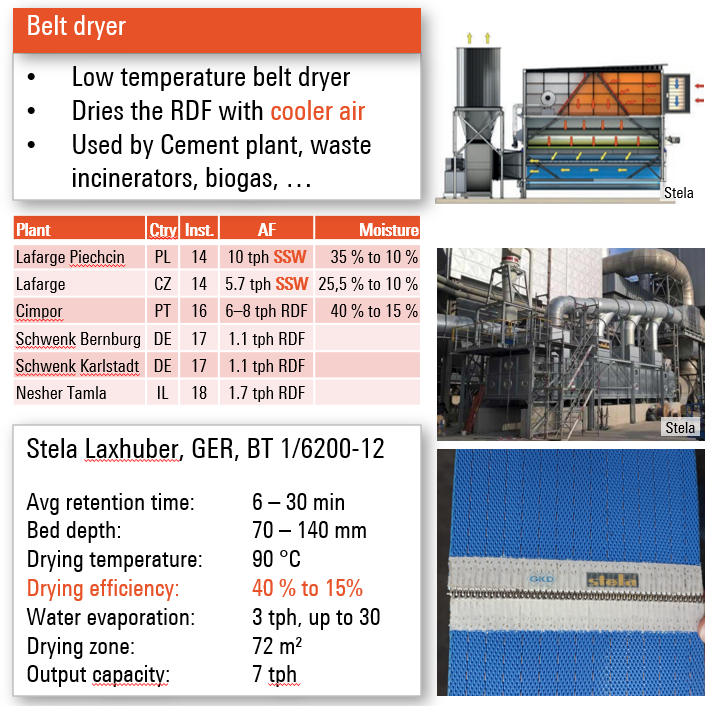

Stela Low Temperature Belt Dryer Drying Technology

Stela Belt Dryer is a drying technological system designed for drying a variety of wet materials, including biomass, sewage sludge, and animal feed.

Stela Belt Dryer is a drying technological system designed for drying a variety of wet materials, including biomass, sewage sludge, and animal feed.

The dryer works by passing the material through a heated chamber while it is transported on a conveyor belt. The hot air is generated by a combustion chamber and circulated through the drying chamber by a fan.

The dryer is energy-efficient, as the hot air is recirculated and the combustion chamber is designed to burn low-grade fuels.

Dryer selection according to drying products

Stele Belt Dryer is widely used in industries such as agriculture, forestry, and waste management. It has applications in producing fuel pellets, animal feed, and fertilizer, as well as in the treatment of sewage sludge. The dryer can handle large volumes of material and has a low environmental impact, making it a popular choice for sustainable processing.

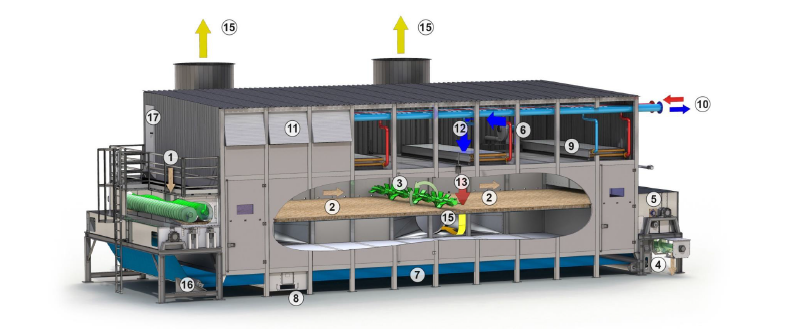

Belt dryer simply explained

A belt dryer, sometimes also referred to as a belt cooler, is a machine that ensures particularly gentle product treatment. Your resource, eg corn, is first fed into an inlet chamber as wet material and then runs through the drying chambers on horizontally arranged, perforated drying belts.

Heating gases flow through or over it and thus dry continuously and evenly. The drying room is divided into several chambers, each of which can be equipped with a circulating air fan and a heating register. This allows each dryer cell to be controlled individually.

The product flow rates of the drying/cooling air can be varied in each cell. In addition, the transport speed of the material to be dried can be varied, which provides an additional parameter for setting the drying time of the material. Both the heating and cooling of the cells can be direct or indirect. All heating media such as oil, steam, warm water or hot gases can be used for this.

Belt dryer of the highest quality

Our belt dryers impress with their durability and are individually manufactured according to the highest quality standards. Already in the third generation, we use the latest drying technologies in our belt dryers.

Regardless of which product you want to dry and prepare professionally, together we will find the right belt dryer. For special requirements, we adapt the respective drying solution individually for you.

Main benefits of Stela Belt Dryer

- Provide efficient solutions for drying variety of wet materials

- Dryer to dry materials to a consistent moisture content

- Flexible and customizable as dryer modular design allows for easy expansion and customisation to meet different industry production needs

- By utilising alternative fuel for cement industry it helps by:

- reducing green house gas emissions

- lowering your fuel costs

- reduce dependence of fossil fuels

- landfill destined waste reduction

- sustainable development

In summary, Stela Belt Dryer is an efficient, reliable, and flexible solution for drying wet materials.

Belt Dryer references

Customers from all over the world trust in our belt dryers. A total of over 4000 systems have already been implemented. It doesn’t matter whether it’s fruit, kernels, grain, blossoms, activated carbon, wood and plastics or even sewage sludge

Individual customers, customised solutions

Your product is not listed? No problem! In our in-house laboratory, we can analyse your product for its specific drying properties and record drying curves. For larger-scale tests, we have a pilot plant available, which we lend to our customers for testing purposes so that they can easily carry out tests directly on site. Stela will find ways and means to develop and realise the special technical solution for you!

- Agriculture – Maize, Wheat, Spelt, Sunflower seeds, Soybeans, Rapeseed, Oats, Barley, Peas, Paddy rice, Field beans

- Special crops – Emmer, Buckwheat, Millet, Amaranth, Quinoa, Triticale, Food and Feed industry, Herbs & Spices, Fruits, Vegetables, Snacks, Nuts, Cereals, Pet Food & other

- Biomass – Timber industry, Pellet industry, Energy production

- Recycling industry – Sludges, Alternative fuels

- Special products – Coconut fibres

- Further products – Apple rings | Orange peel | Apple slices | Oyster Mushrooms | Banana slices | Cooton spit | Bentonite | Spent grains | Pumice stone | Beans | Mushrooms | Special chemical products | Cobalt oxide | Cranberries | Dates | Iron II sulpate | Strawberries | Eucalyptus bark | Extrudates | Colouring granules | Film chips | Breakfast cereals, coded and uncoded | Crushed aerated concrete | Chopped corn | Vegetables | Grass | Grass seed | Green spelt | Wood chips | Blueberries | Wood shavings | Currants | Coffee beans | Cocoa | Kaolin | Carrots | Diced carrots | Kiwi pomace | Sewage sludge | Clover | Garlic | Coal pellets | Compost | Herbs | Caraway seeds | Pumpkin seeds | Lentils | Alfalfa | Macadamia nuts | Maize | Almonds | Microchips | Miscanthus | Nuts | Wet shavings | Fruits | Oregano | Organic fibres | OSB-Strands | Paper balls | Paper sludge | Paprika | Pellets | Pet food | Parsley | Pepper | Peppermint | Polystyrene | Cranberries | Rice | Bark | Rye malt | Sultanas | Sägespäne | Chives | Chocolat sprinkles | Celery | Mustard seed | Silicon carbide | Solid shredded waste | Asparagus | Spitting substances | Straw | Tomatoes | Grape marc | Cellulose granules | Chicory | Sugar beet pulp | Onions