Easier Boiler Cleaning After Fuel Additive

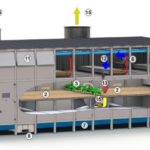

What is a boiler

A boiler is a closed vessel in which fluid (generally water) is heated to generate either hot water or steam. Heat from the combustion of a fuel source, such as gas or oil, is transferred to the water or steam, which is then circulated throughout a building or system to provide heat. Boilers are commonly used for heating homes, generating electricity, or providing hot water for heating or other purposes. They can also be used in industrial applications to generate steam for power or process heat.

For industrial purpose, a boiler is used for transferring combustion heat into water until it becomes steam. Once the heat transferred, the steam is then usable for transferring the heat to a processing plant. This is a very efficient heat transfer purpose for a processing plant, however, over time, minerals from the feed water deposit onto the heat transfer surface and begin to obstruct the efficiency and increase the operating costs.

An annual cleaning of boiler tubes will dissolve and remove the calcium, magnesium, rust, and other deposits into the solution without harming the components within boiler.

Cleaning the boiler tubes regularly will improve the boiler’s technical and economic performance.

How to clean a boiler

Cleaning a boiler can involve multiple steps, depending on the type of boiler and the level of buildup. Here are some general steps that can be followed to clean a boiler:

- Shut down the boiler and let it cool.

- Remove any dust or debris from the exterior of the boiler using a soft-bristle brush, vacuum, or compressed air.

- Clean the combustion chamber and flue passages using a wire brush or vacuum.

- Flush the boiler’s water system to remove any sediments.

- Inspect all boiler components for signs of damage, corrosion, or leaks.

- Conduct regular maintenance to prevent buildup and other issues to arise.

It is important to always refer to the manufacturer’s guidelines or consult a licensed professional for specific instructions on how to clean a particular type of boiler.

After using organic fuel additive

Fuel additive can be used in boilers to improve combustion efficiency, reduce emissions, and minimize corrosion and deposits. Common additives used in boilers include combustion catalysts, corrosion inhibitors, and anti-foaming agents. These additives can help improve boiler performance and longevity, while also reducing maintenance costs. However, it is important to only use additives that are compatible with the particular type of fuel and boiler being used.

The user of this particular boiler has been using SUMBU Organic Fuel Additive for one cycle.

Upon the shutdown schedule is due, the boiler has been showing remarkable good result, which allowed the cleaning contractor a much easier job.

Contact us

email : sales [at] cemax [dot] com [dot] my whatsapp : +60 16 207 5400