FAQ on Organic Waste into Compost for Food Production

What is organic waste composting, and why is it important for food manufacturers

Organic waste composting is the process of decomposing organic materials, such as food scraps, yard waste, and agricultural residues, into nutrient-rich compost through microbial activity. Food manufacturers produce a significant amount of organic waste, including food scraps, peelings, and expired products. Composting this waste reduces landfill contributions, conserves resources, and produces a valuable soil amendment for agricultural use or landscaping.

How does composting benefit food manufacturers

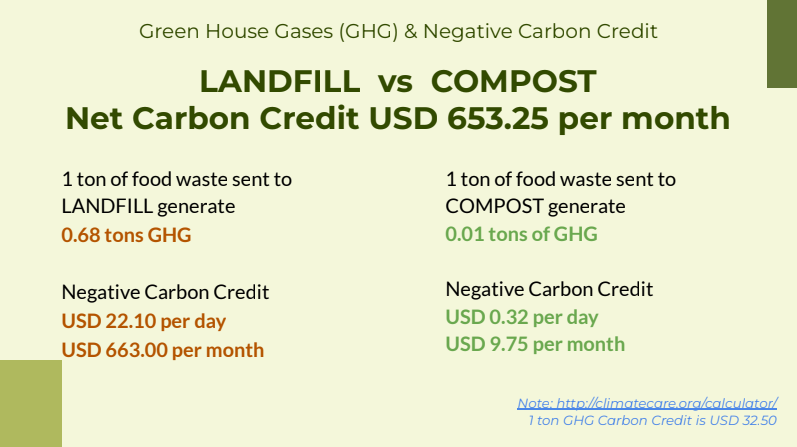

- Waste Reduction: Composting reduces the volume of organic waste sent to landfills, decreasing disposal costs and environmental impact

- Resource Conservation: Instead of discarding organic waste, composting transforms it into a valuable resource for soil enrichment, reducing the need for chemical fertilizers

- Regulatory Compliance: Many regions have regulations or incentives encouraging businesses to divert organic waste from landfills. Composting can help food manufacturers comply with these requirements

- Corporate Social Responsibility: Implementing sustainable waste management practices, such as composting, aligns with corporate sustainability goals and enhances brand reputation

What is a composting machine, and how does it work

A composting machine, also known as a composting system or composter, is a device designed to accelerate the composting process by providing optimal conditions for microbial activity.

- These machines typically control factors such as temperature, moisture, and aeration to promote efficient decomposition

- Some composting machines use mechanical mixing or turning mechanisms to aerate the compost pile, while others rely on forced aeration or microbial inoculants to facilitate decomposition

How does a food manufacturer set up a composting system on-site

- Assessment: Begin by conducting a waste audit to determine the quantity and composition of organic waste generated

- Selection: Choose a composting machine suitable for the scale of operations and type of organic waste produced

- Location: Select a suitable location for the composting system, considering factors such as space availability, access to utilities, and proximity to waste sources

- Training: Train staff on proper waste segregation, composting techniques, and equipment operation to ensure successful implementation

- Regulatory Compliance: Obtain necessary permits or approvals from local authorities if required for on-site composting operations

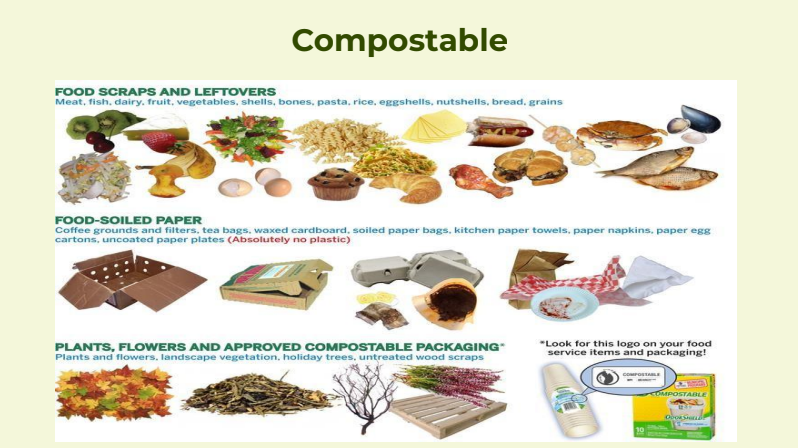

What types of organic waste can be composted using a composting machine

- Food Scraps: Fruit and vegetable trimmings, peels, cores, expired products, and plate scrapings

- Agricultural Residues: Crop residues, spent grains, and other by-products of food processing

- Yard Waste: Grass clippings, leaves, and prunings (if applicable and allowed by local regulations)

How long does it take to produce compost using a composting machine

The composting process duration varies depending on factors such as waste composition, machine capacity, operating conditions, and composting method. Typically, conventional composting machines can produce compost in weeks, significantly faster than traditional composting methods.

What are the key factors influencing successful composting with a composting machine

- Carbon-to-Nitrogen Ratio: Maintaining a balanced carbon-to-nitrogen ratio (C/N ratio) in the compost pile promotes microbial activity and ensures efficient decomposition

- Temperature: Optimal composting temperatures typically range from 110°F to 160°F (43°C to 71°C) to facilitate microbial growth and pathogen reduction

- Moisture: Adequate moisture levels (typically 50% to 60% moisture content) are essential for microbial activity and decomposition

- Aeration: Proper aeration ensures oxygen supply to microbial communities and prevents anaerobic conditions that lead to unpleasant odors and slow decomposition

What are the potential challenges or drawbacks of composting organic waste with a composting machine

- Initial Investment: Composting machines may require a significant initial investment, depending on the size and technology

- Maintenance: Regular maintenance, including equipment cleaning, monitoring, and occasional repairs, is necessary to ensure optimal performance

- Odor Management: Improper composting practices or conditions can lead to odors, which may require mitigation measures such as odor control systems

- Regulatory Compliance: Composting operations must comply with local regulations governing waste management, environmental protection, and odor control

Can the compost produced from organic waste be used on-site, or is it sold or donated

- Food manufacturers can use the compost produced on-site for landscaping, soil amendment in green spaces, or even as a component in potting mixes for plants

- Alternatively, excess compost can be sold or donated to local farmers, gardeners, or landscaping companies

Are there any resources or organizations that can assist food manufacturers in implementing composting programs

- Government Agencies: Local environmental or waste management agencies may provide guidance, resources, or financial incentives for implementing composting programs

- Nonprofit Organizations: Environmental organizations and composting associations often offer educational materials, workshops, and technical assistance to businesses interested in composting

- Consultants and Suppliers: Waste management consultants and equipment suppliers can offer expertise in designing, implementing, and maintaining composting systems tailored to specific needs

This FAQ provides a comprehensive overview of organic waste composting for food manufacturers, covering key concepts, benefits, implementation steps, and potential challenges. For further guidance or specific inquiries, food manufacturers are encouraged to consult CEMAX or local authorities familiar with composting regulations and best practices.