KIMA KilnCooler Rotary Kiln Hotspot Cooling Intelligent Water Jet Spray

Kiln cooling using water based KilnCooler

Control your kiln shell temperature with a water based kiln cooling system. Reliable and effective cooler for kiln shell.

Due to the increasing usage of secondary fuels, which are relatively in-homogeneous, there are more fluctuations in the burning process. This leads to increased burden for the refractory and the kiln shell hot-spots may occur. In order to reduce this burden, large cooling fans, which are blowing ambient air, are widely used.

Unfortunately, this type of cooling shows some dis-advantages:

- due to the low heat capacity of air, a huge throughput is needed

- the consumption of electrical energy is high

- the cooling cannot be targeted specifically to a hot-spot on a circumference

- fans emit a substantial amount of noise

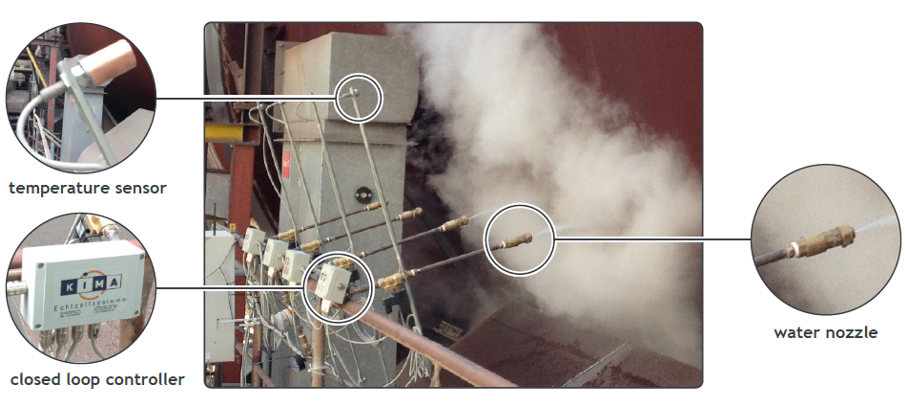

To overcome these dis-advantages KilnCooler uses water-spray nozzles and precise dosing valves, which are controlled by an infrared temperature sensor. The water-spray of an individual nozzle is switched on only, while its infrared sensor detects a hot-spot.

Efficiency by Water Cooling

- efficient cooling

- flexible usage for hot-spots and complete kilns

- ready-to-use modules

- easy installation or relocation

- low noise emission

- controlled by a FUZZY-controller for targeted cooling on kiln’s circumference, i.e. only the hot-spot is cooled down, not necessarily the entire circumference

Cooling Down a Hot-spot

By application of KilnCooler, a hot-spot can be cooled down rapidly but carefully, avoiding any shrinkage of the kiln shell – cooling rate is up to 2 Kelvin per minute. After cool-down, the shell temperature is kept on its nominal value, thus eliminating mechanical tensions.