REFRATECHNIK Refractory in Malaysia

Refratechnik refractory in Malaysia

How does refractory helps in Malaysia and the global economy?

In order to meet the globally increasing demand for cement, high output and energy-saving lining systems have been developed in the industrialized countries and introduced throughout the world.

One of the primary result of these these developments is the pre-calciner kiln with a short rotary kiln section.

The use of alternative fuels has also taken on a new significance.

Keeping pace with this technology requires suitable fire brick products and lining systems: the conditions inside the kiln are a determining factor of its service life.

“Without refractory materials, we could not use vehicles, cell phones, computers, or our homes as we know them today. However, they make all of our lives easier and more beautiful. Therefore I like to contribute with my work to make modern refractory materials”. – Tom Axmann | R&D Manager at Refratechnik Asia

Shaped refractory brick by Refratechnik Asia

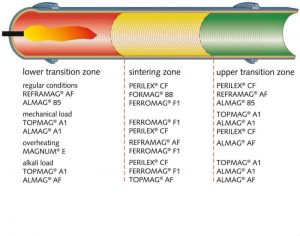

TOPMAG® A1

TOPMAG® A1

- Magnesia-Fused Spinel

- Upper and lower transition zones subject to severe mechanical load; tyre section, in case of redox conditions and alkali attacks, chrome ore free

TOPMAG® AF

- Magnesia-Fused Spinel

- Upper and lower transition zones subject to severe thermochemical load, chrome ore free

REFRAMAG® AF

- Magnesia-Spinel

- Upper and lower transition zones as well as burning zone subject to normal thermochemical load, chrome ore free

REFRAMAG® S

- Magnesia-Spinel

- Burning zone subject to thermochemical load, chrome ore free

PLEOMAG 90

- Magnesia-Pleonaste

- Upper transition zone and burning zone subject to thermochemical load, promoting coating formation, chrome ore free

KRONAL® 63 AR

- Mullitizised raw material, Silicon Carbide

- Kiln outlet, cooler inlet

KRONAL® 60 AR

- Andalusite, Silicon Carbide

- Safety zone subject to high alkali load and increased temperatures, preheater, calciner, kiln hood, cooler

REFRALUSIT® 63

- Andalusite

- Calciner, kiln hood, lime sludge kiln, combustion chamber, cooler

KRONEX® 87

- Bauxite (Gibbsite Type)

- Rotary kiln outlet, kiln hood, cooler, tertiary air duct

KRONEX® 60

- Bauxite, Fireclay

- Safety zone, calciner, cooler

KRONEX® 40

- Special alkali resistant fireclay

- Inlet zone, chain zone, preheating zone, preheater, calciner, cooler

KRONEX® 30

- Special alkali resistant fireclay

- Inlet zone, chain zone, preheating zone, preheater, cooler, tertiary air duct

REFRATHERM® 150

- Refractory lightweight materials

- Preheating zone, lime sludge kiln

Refractory concrete

In constant efforts to intensify customer services and improve products, Refratechnik has developed innovative refractory concrete grades.

In constant efforts to intensify customer services and improve products, Refratechnik has developed innovative refractory concrete grades.

These low cement castable (LCC) are state of the art products in refractory technology and meet all the demands of processing and application behavior.

In order to obtain a long service life, even under the harshest conditions, it is most essential that the refractory concretes be installed correctly.

Our supervisors are on hand to provide technical assistance and supervision during installation.

The concretes are produced in Gornal/Spain, and production is subject to the strict demands of DIN EN ISO 9001 and 14001.

The castable product range includes the following grades:

- Regular Cement Castable (RCC)

- Low Cement Castable (LCC)

Refractory products for iron and steel

For all areas of production in the steel industry where there is a demand for refractory products, we offer concepts and solutions which are adapted fundamentally to our customer`s individual situation.

For all areas of production in the steel industry where there is a demand for refractory products, we offer concepts and solutions which are adapted fundamentally to our customer`s individual situation.

In this endeavor, we are able to draw on our extensive range of products.

Amongst other things, we offer individual concepts and solutions for:

- Converters

- Electric arc furnaces

- Steel casting ladles

- Pig-iron vessels

- Coking plants

- Powder metal facilities

- Direct reduction plants

- Blast furnaces

- Rolling mill furnaces

- Heat treatment furnaces

Refractory brick for primary aluminium

In primary aluminium production, furnace service life is an decisive economic criteria for the overall profitability.

In primary aluminium production, furnace service life is an decisive economic criteria for the overall profitability.

With our specialized products for pot-cells and anode baking furnaces, you can rely on top quality and safety “Made in Germany”.

Intelligent technology for the primary aluminium: Pot-cells; Anode baking furnaces.

Refractory materials for aluminium cast house

More and more high-performance regenerative burners are being used world-wide.

More and more high-performance regenerative burners are being used world-wide.

For this high-temperature application, we have developed a series of products which permit temperatures far in excess of 1200 °C in direct contact with aluminium.

Amongst other things, we offer individual concepts and solutions for the aluminium cast house:

- Smelting and holding furnaces

- Multi-chamber furnaces

- Rotary drum furnaces

- Shaft furnaces

- Transport ladles

- Electrically heated furnaces (Channel induction furnaces)

- Prefabricated components / Runners

Fire brick for non ferrous metal

The processes performed to acquire the purest non-ferrous metals, such as lead, copper, nickel, tin, zinc or PGM and even various ferro-alloy elements are diverse and complex, as are the aggregates developed for this purpose.

Refractory supplies for chemistry, environmental and energy industries

Refractory concepts are provided amongst other things for the following technologies:

- Power stations based on fossil fuels (black coal, brown coal, oil, gas)

- Waste incinerating plants

- Hazardous waste incinerating plants

- Waste gas purification and post-combustion for industrial smelting and holding furnaces

- Burning chambers for hot air-supply

- Fluidized bed combustion

- Recirculating shafts

- Soot generators

- Ethylene crackers

- Naphtha crackers

- Sulphuric acid incinerating plants

- Gas torches