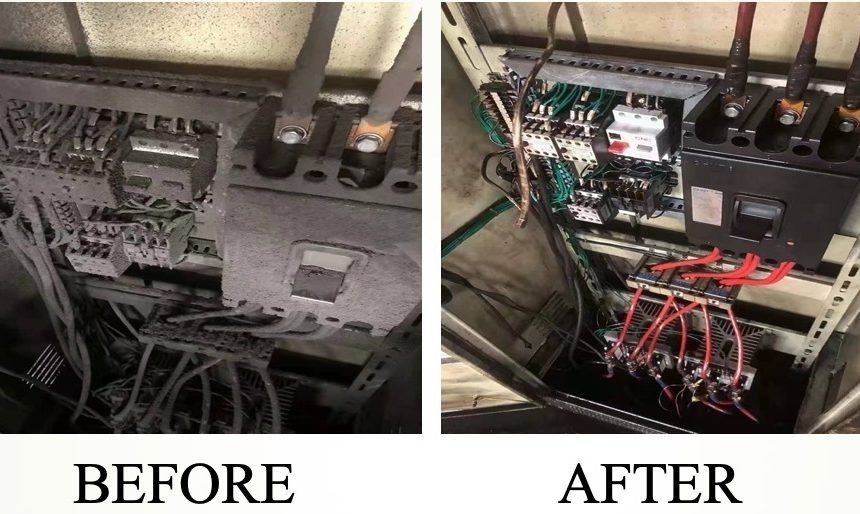

Safe Cleaning Electrical Cabinet and Substation Malaysia

The decontamination method of the product is a pure physical method in which nano-molecules are decomposed, wrapped, and then taken away by liquid pressure, which can efficiently remove dust, oil, carbon stains, salt, moisture, and metals attached to the equipment when the equipment is charged and running normally.

After use, the service life of the equipment can be extended, the loss of the equipment can be reduced, and the short-circuit ignition and poor heat dissipation of the equipment can be avoided. The maximum applicable voltage of power and electrical equipment cleaning products is 500kV, and the network communication equipment cleaning products can remove equipment static electricity.

Advantages of nano live cleaning

- Safe, reliable, highly insulated, and non-flammable, which greatly improves the safety of use.

- Non-corrosive, and neutral pH value, which brings no damage to equipment.

- Colorless, odorless, and non-toxic, which is harmless to personnel health and environmental friendly.

- Strong water repellency.

- Greatly improve performance.

How to do nano live cleaning

Using nano live cleaning methods for cleaning electrical cabinets and substations involves utilizing nanotechnology-based cleaning agents and techniques to achieve thorough cleaning while minimizing the risk of damage to sensitive electrical components. Here’s a guide on how to apply nano live cleaning method safely and efficiently:

- Select Nano Cleaning Agents: Choose nano cleaning agents specifically designed for electrical equipment cleaning. These agents typically contain nano-sized particles that can penetrate and lift dirt and contaminants without damaging the equipment.

- Turn Off Power: Before starting the cleaning process, ensure that all power to the electrical cabinet or substation is turned off and locked/tagged out to prevent accidental energization.

- Preparation: Inspect the electrical equipment for any signs of damage or loose connections. Cover sensitive electrical components with protective materials to prevent direct contact with cleaning agents.

- Application: Apply the nano cleaning agent using a sprayer or microfiber cloth. Follow the manufacturer’s instructions for dilution ratios and application methods. Ensure even coverage over the surfaces to be cleaned.

- Allow Dwell Time: Allow the nano cleaning agent to dwell on the surfaces for the recommended amount of time to loosen dirt and contaminants effectively. Avoid letting the cleaning agent dry on the surfaces.

- Agitation (if necessary): For stubborn stains or heavily soiled areas, gently agitate the cleaning agent using a soft-bristled brush or sponge. Be cautious not to apply excessive force that could damage the equipment.

- Rinsing (if necessary): Some nano cleaning agents may require rinsing with water to remove residue. Use a low-pressure water source or a damp cloth to rinse off the cleaning agent thoroughly. Avoid spraying water directly onto electrical components.

- Drying Time: Allow the cleaned surfaces to air dry completely before restoring power. Use absorbent materials or air blowers to accelerate the drying process if necessary.

- Inspection: After cleaning, visually inspect the equipment for any signs of residue or damage. Ensure that all protective covers and materials are removed before restoring power.

- Dispose of Waste Properly: Dispose of any waste materials, such as used cleaning agents and cloths, in accordance with local regulations and environmental guidelines.

- Safety Precautions: Wear appropriate personal protective equipment (PPE), including gloves and safety goggles, to minimize the risk of exposure to cleaning agents.

- Training and Supervision: Ensure that personnel performing the cleaning tasks are properly trained in handling nano cleaning agents and familiar with electrical safety procedures.

By following these steps, you can effectively clean electrical cabinets and substations using nano live cleaning methods while minimizing the risk of damage to sensitive equipment. Always prioritize safety and adhere to manufacturer instructions when using cleaning agents and techniques.

Contact us

email : patrick [at] cemax [dot] com [dot] my whatsapp : +60 12 376 0589