SILOMANN Silo Cleaning

History of Silo Cleaning

Silo cleaning was in demand ever since product was stored in dry bulk storage. Most noteworthy scenario such as build-up, dead-stock, contamination and infestation are always the major challenges.

Silo cleaning was in demand ever since product was stored in dry bulk storage. Most noteworthy scenario such as build-up, dead-stock, contamination and infestation are always the major challenges.

Therefore, for many years, companies have been seeking for solutions on efficiency, cost effectiveness and most of all – SAFETY.

Years after years, hundreds of near-miss incidents and severe accidents had taken place globally. Especially some cases lead to unfortunate death.

As a result, most countries nowadays have classified confined space entry as occupational hazard under their Local Government Regulations, and Confined Space Legislation.

When did we start silo cleaning service?

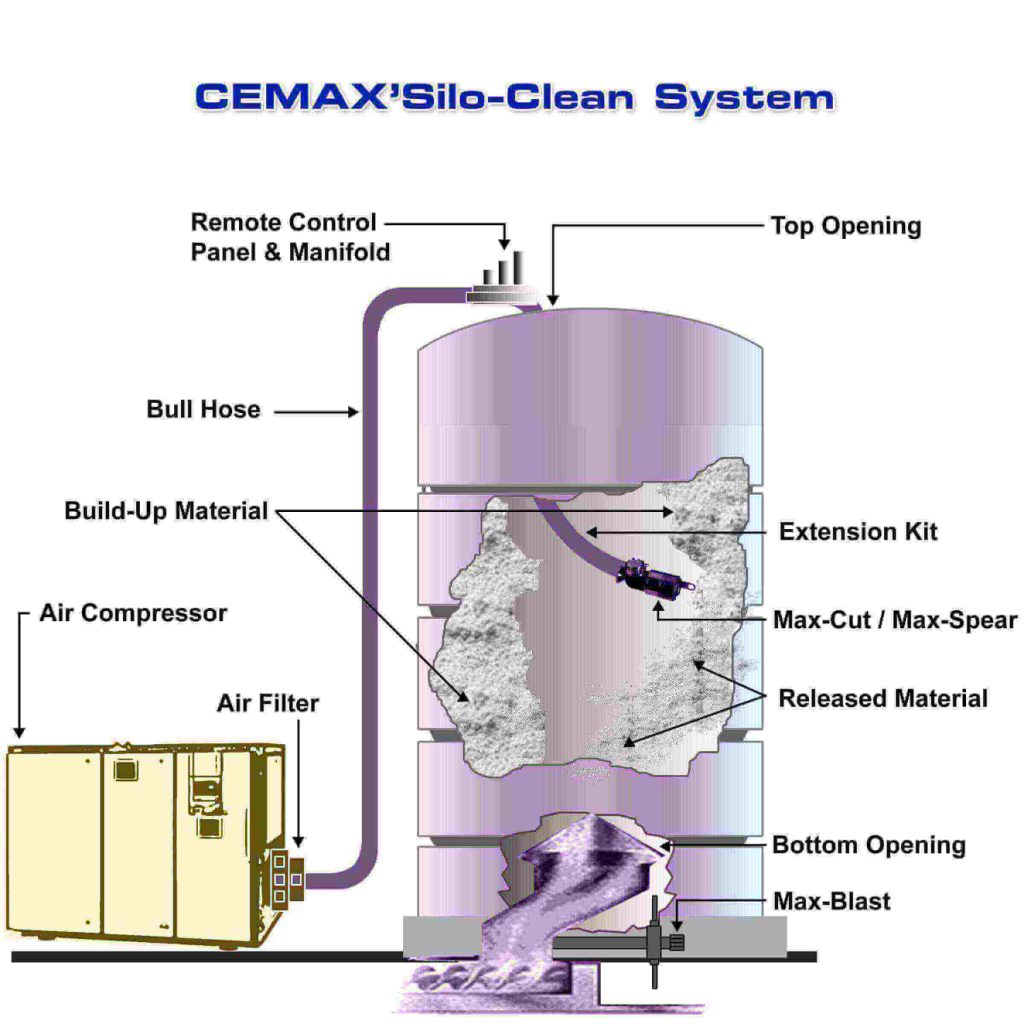

Since 2004, SILOMANN have been doing research and development for better silo services and technologies. In addition, we have upgraded the transferred technologies from various engineering resources. The basic idea is to achieve a combination of fast and effective procedures, while creating sufficient material-refractive effect for clearing the dead-stock.

Since 2004, SILOMANN have been doing research and development for better silo services and technologies. In addition, we have upgraded the transferred technologies from various engineering resources. The basic idea is to achieve a combination of fast and effective procedures, while creating sufficient material-refractive effect for clearing the dead-stock.

Furthermore, we have gained experiences and understand the importance of engineering especially dealing with confined space. Therefore, we are continuously developing new products, innovative solutions and safety features to make it the safest, most reliable and most effective system.

What is the goal of silo cleaning?

SILOMANN undertake projects with qualified teams who are fully equipped with engineered methodologies for silo cleaning services. The ultimate goal is to loosen and to clean compacted products til a condition, which is deemed “safe for human-entry” standard.

SILOMANN undertake projects with qualified teams who are fully equipped with engineered methodologies for silo cleaning services. The ultimate goal is to loosen and to clean compacted products til a condition, which is deemed “safe for human-entry” standard.

In addition, we strictly follow the confined space entry rules emphasized by Occupational Safety and Health of each country. Which is also equivalent to the Regulation 13 of Malaysian Factories and Machinery Act (Safety, Health and Welfare), and Regulations 1970.

What is the types of silo?

The characteristics of a storage silo suitable for our silo cleaning tools can be classified as follows:

The characteristics of a storage silo suitable for our silo cleaning tools can be classified as follows:

Type – silo, bin, bunker, hopper or tank

Shape – round or square

Construction – concrete, steel, corrugated iron, fibre or fabric

Capacity – up to 25,000 tonnes

Product – vary in particle size, consistency and density

Industry – cement, chemical, feed and grain, food, etc..

Why do you need silo cleaning?

4 common reasons for cement silo cleaning or flour silo cleaning:

4 common reasons for cement silo cleaning or flour silo cleaning:

- Maintenance – when the silo requires inspection or repair, but build-up material still presents and interrupts repair works.

- Flow Disruption – when the build-up material either reduces the material flow or completely plugs the silo taking if off-line, causing serious production slow down or even stoppage.

- Product Change – when the production department changes its demand, and results in storing a different material.

- Contamination – when the needs to purge the received contaminated material, or the natural degradation of the stored material required routine cleaning to remove scaling or sub-standard material.

What is the advantages of SILOMANN silo cleaning methods?

SILOMANN Silo Cleaning methods are proven to have the following advantages:

SILOMANN Silo Cleaning methods are proven to have the following advantages:

Safety

- No human-entry in confined space.

- Safely remove flammable, explosive, hazardous and toxic products.

- Ceiling, wall, lining, bottom and air slide are not in risk of damage.

- Compliance to the Regulation 13 of Malaysian Factories and Machinery Act (Safety, Health and Welfare), and Regulation 1970.

Hygiene

- Dry process, means no contamination from water, chemical or explosive.

- Environmental friendly and no contamination.

- Regular cleaning would ensure product Quality Control.

- Higher standard of cleanliness.

Economical

- Cost reduction in legislation of confined space.

- Dead-stock recycling.

- Storage capacity improvement.

- Compliance to Quality Assurance and ISO.

Speed

- Averagely faster than conventional methods.

- Simultaneously clean more than one silo.