CEMAX ENERGY Solid Recovered Fuel Sorting Plant

What is Solid Recovered Fuel

Solid Recovered Fuel (SRF) is a type of “fuel” used by certain combustion industries as a way to reduce emissions. Cement plants, lime plants, and coal-fired power plants are replacing a portion of their fossil fuels (coal), to reduce operating costs too.

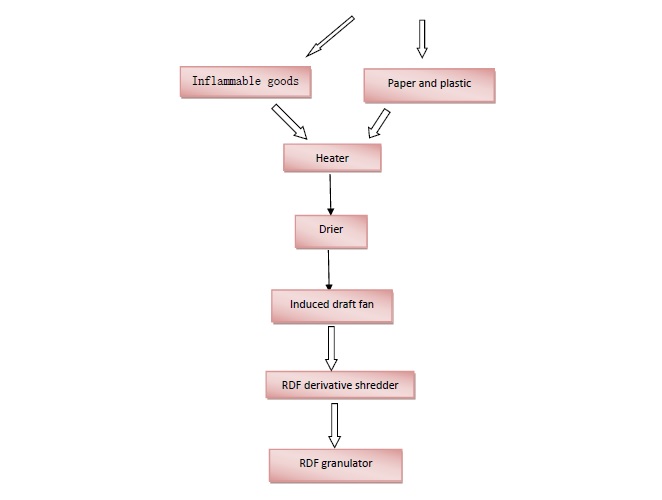

Unlike Refuse Derived Fuel (RDF), SRF is produced by shredding selected solid waste and by-products with good recoverable calorific value, more refined and more efficient.

SRF is consisting of combustible materials from waste generators of commercial and industrial (C&I), and construction and demolition (C&D). Examples of good waste materials are non-recyclable plastics, paper cardboard, labels, and other corrugated materials.

SRF is part of RDF in the fact that the production is to reach quality standards and thermal recovery on European SRF quality.

SRF plant basic processing

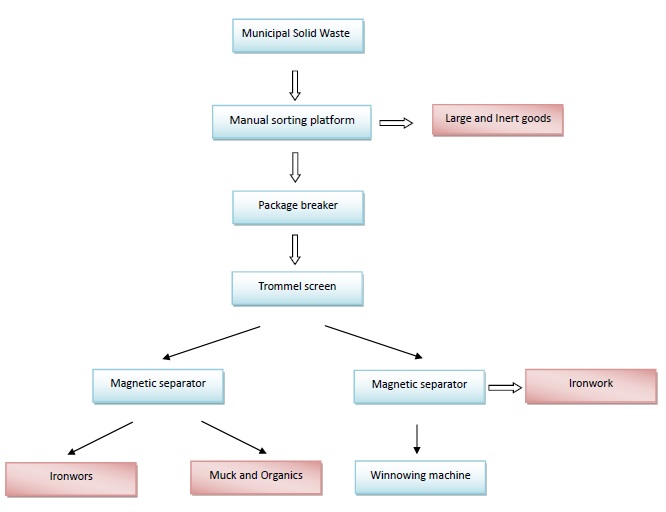

The processing line includes equipment for sorting, screening, separating, drying, and shredding. The outcome is high-calorific RDF or SRF.

Pretreatment of solid waste

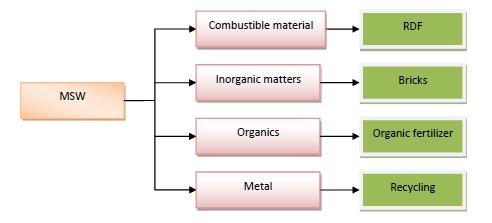

Classify municipal solid waste (MSW) into four different materials which are organics, inorganic, combustible, and metal. And according to the follow-up needs to process the materials for different applications, such as composting organic fertilizer, making green bricks, making RDF or SRF, and the secondary recycling.