CEMAX ENERGY Tire Derived Fuel

Tire Derived Fuel

Tire Derived Fuel (TDF) is processed from shredded scrap tires. Scrap tires could be mixed with coal or alternative solid fuels, such as wood or chemical wastes, to be burned in cement kilns, pulp paper mills, or power stations. Emissions from TDF are not very much different from other fossil fuels, as long as the combustion component is well managed.

Tire Derived Fuel (TDF) is processed from shredded scrap tires. Scrap tires could be mixed with coal or alternative solid fuels, such as wood or chemical wastes, to be burned in cement kilns, pulp paper mills, or power stations. Emissions from TDF are not very much different from other fossil fuels, as long as the combustion component is well managed.

Tired Derived Fuel has a high heating value. Therefore, scrap tires are considered a beneficial use, better to recover the energy from a tire rather than landfill it.

There are several advantages to using tires as fuel:

- Tires produce the same amount of energy like petroleum and 25% more energy than coal;

- The ash residues from TDF may contain lower heavy metals content than some coals;

- Results in lower NOx emissions when compared to many US coals, particularly the high-sulfur coals.

Scrap Tires in Cement Kilns

Millions of scrap tires per year are consumed as fuel in cement kilns. The cement plant burns scrap tires as fuel in kilns. The use of whole scrap tires as kiln fuel is possible for some design of kilns. The advantage is no shredding cost compared to tire chips.

Tire Derived Fuel in Pulp Paper Mills

Pulp paper mills have large boilers, that are used to supply energy for making paper. This energy is normally supplied by pulp and wood waste, however, heat values and moisture content are not constant. Therefore, the mills often add-on other fuels, such as Diesel or TDF, to stable the operation.

Tire Derived Fuel in Power Stations

In the power industry, boilers typically burn coal to generate electricity. TDF is often used as an extra fuel because of its higher heating value, lower NOx emissions, and competitive cost as compared to coal. Cyclone boilers are the most used of all the power boilers for burning TDF because no changes to be made to the boiler itself which reduces the capital investment.

Tired Derived Oil in Industrial Boilers

Many industrial facilities are using Tire Derived Oil (TDO) in their boilers to supplement their fuel usage. Industrial boilers are smaller and typically use a variety of fuels.

Other application areas of Tire Derived Oil

Typical industrial application of TDO as a fuel to generate and power:

- Furnaces

- Hot water generators

- Hot air generators / Steam boiler

- Thermic fluid heater / Thermal oil heater

TDO combustion for heat is the most simple and straightforward application.

TDO can replace both heavy and light fuel oil (LFO).

TDO co-combustion in an industrial, natural gas-fired power station has been successfully demonstrated.

With additional equipment, TDO can be further processed to give a Diesel and Gasoline equivalent fuel, which can be used in Electric Generators and Diesel Pumps. Its to be mixed with 50% Diesel.

Benefits of using Tire Derived Oil

- TDO reduces the number of fossil fuels that would otherwise be consumed.

- TDO is less expensive than fossil fuels.

- TDO is renewable and locally produced from organic waste.

- TDO can be stored and transported similarly to petroleum-based products.

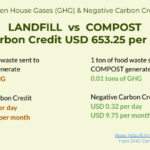

- TDO is greenhouse gas neutral and can generate carbon dioxide credits.

- TDO generates lower NOx emission than Light Fuel Oil in gas turbines and Diesel in stationary diesel engines.

Analytical Report of Tire Derived Oil

TDO standard analytical report:

- Density at 15°C = 0.9156 kg/L

- Kinematic Viscosity at 40 °C = 3.081 mm²/s

- Kinematic Viscosity at 50 °C = 2.982 mm²/s

- Flash Point = <40 °C

- Pour Point = -30 °C

- Carbon Residue = 0.28 % (m/m)

- Ash = <0.001 mass %

- Water by Distillation = <0.05 % (V/V)

- Sulfur = 0.824 mass %